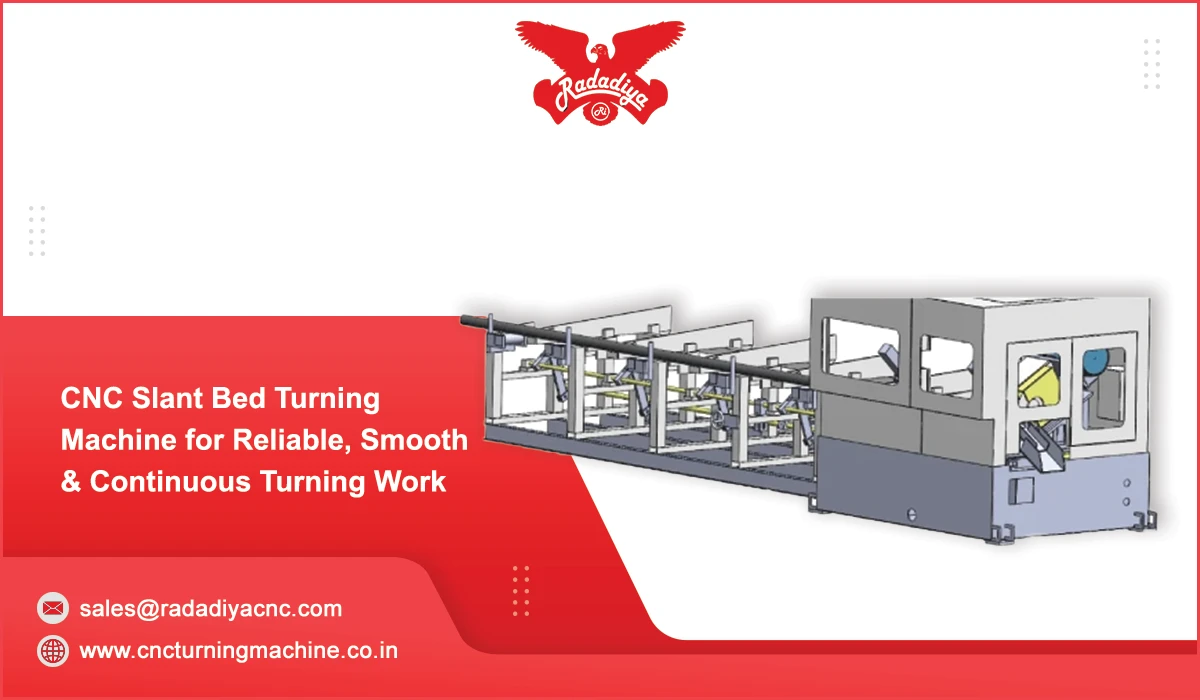

High Performance Cnc Twin Spindle Turning Machine For Complex Component Production

The High Performance CNC Twin Spindle Turning Machine is designed for efficiently producing complex components with high precision. It features two spindles that operate simultaneously on a single setup, which reduces machining time and enhances productivity. This makes it well-suited for industries that demand exactness and consistent output, including automotive, aerospace, engineering, and metal component manufacturing.

This machine is capable of performing various operations such as turning, facing, drilling, and threading all while the part remains in place. The dual spindle design ensures greater accuracy and reliable quality when manufacturing intricate parts. It is particularly effective for component that require tight tolerances and detailed features.

The machine is constructed with a robust and sturdy frame to maintain stability during high-speed operations. Its advanced CNC control system provides user-friendly programming, smooth performance, and precise control throughout the machining process. This versatility makes it suitable for both small-scale and large-volume production need.

KEY FEATURE:

- Single Setup Operation – Multiple processes completed without job removal, reducing handling time

- Rigid Machine Structure – Ensures vibration-free and stable performance during high-speed operations

- Advanced CNC Control System – Easy programming with smooth and precise machine control

- High Production Output – Ideal for mass production and continuous manufacturing

- User-Friendly Operation – Simple controls for easy operation and reduced operator effort

- Consistent Surface Finish – Produces uniform and high-quality finished component