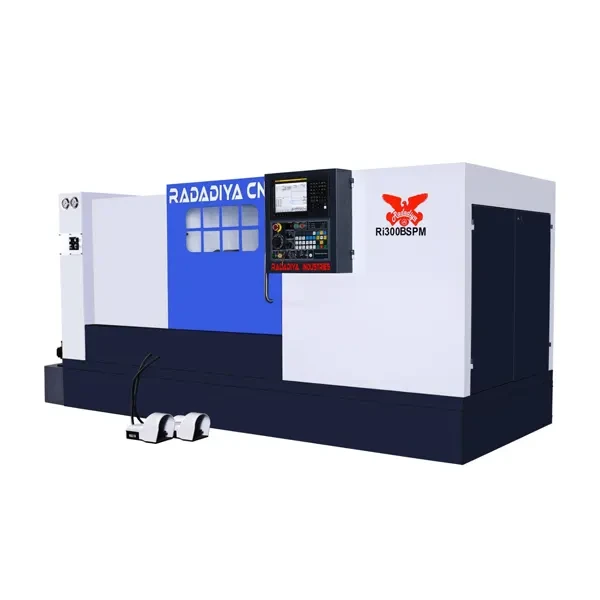

Cnc Roll Turning Machine

Advanced CNC Roll Turning Solutions for Enhanced Productivity

This machine delivers precise machining for large cylindrical components, ensuring high-quality surface finish and accuracy. Engineered for industrial applications, it offers efficient and consistent performance.

Silent Features:

- All main Components, Bed, Headstock, Saddle, Plinth are high quality solid casting.

- High Torque capacity at Head Stock.

- Zero Backlash with Ball Screw.

- Provision For Higher Cutting Force.

- Highest cut up to 10mm.

- Accurate Geometric Dimensions of Fitment Parts.

- Telescopic Cover To Protect Guideways.

- Rough & Finish Machining is Achieved in the Lathe & CNC System Programming.

Cnc Roll Turning Machine

Advanced CNC Roll Turning Solutions for Enhanced Productivity

This machine delivers precise machining for large cylindrical components, ensuring high-quality surface finish and accuracy. Engineered for industrial applications, it offers efficient and consistent performance.

Silent Features:

- All main Components, Bed, Headstock, Saddle, Plinth are high quality solid casting.

- High Torque capacity at Head Stock.

- Zero Backlash with Ball Screw.

- Provision For Higher Cutting Force.

- Highest cut up to 10mm.

- Accurate Geometric Dimensions of Fitment Parts.

- Telescopic Cover To Protect Guideways.

- Rough & Finish Machining is Achieved in the Lathe & CNC System Programming.

Product Specification

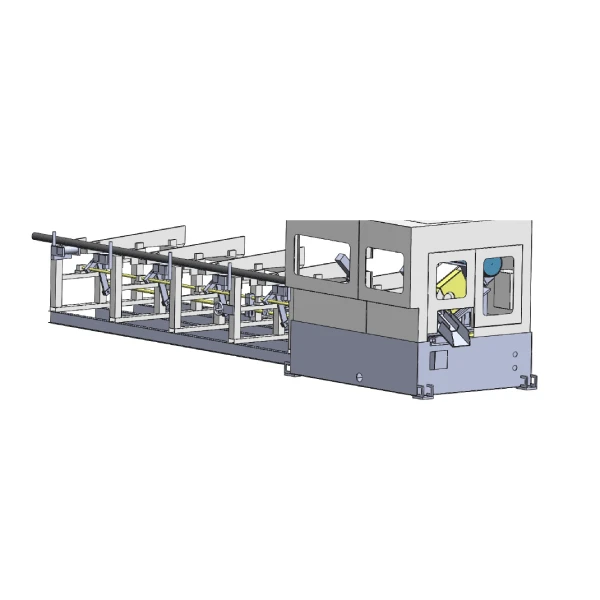

A CNC roll turning machine provides significant advantages in the manufacturing of cylindrical components, making it an essential tool for various industries. With its advanced computer numerical control technology, this machine ensures high precision and consistency, allowing for the production of complex shapes and geometries with tight tolerances. The automated operation minimizes human error and reduces setup times, leading to increased efficiency and faster production cycles. Additionally, CNC roll turning machines are highly versatile, capable of handling a variety of materials, including metals, plastics, and composites, making them suitable for diverse applications from automotive parts to aerospace components.

The robust design and powerful spindle capabilities enable the processing of large and heavy workpieces, while features like programmable feeds and speeds allow for optimal cutting conditions, enhancing tool life and surface finish. Overall, investing in a CNC roll turning machine enhances productivity, reduces waste, and improves the overall quality of manufactured products.