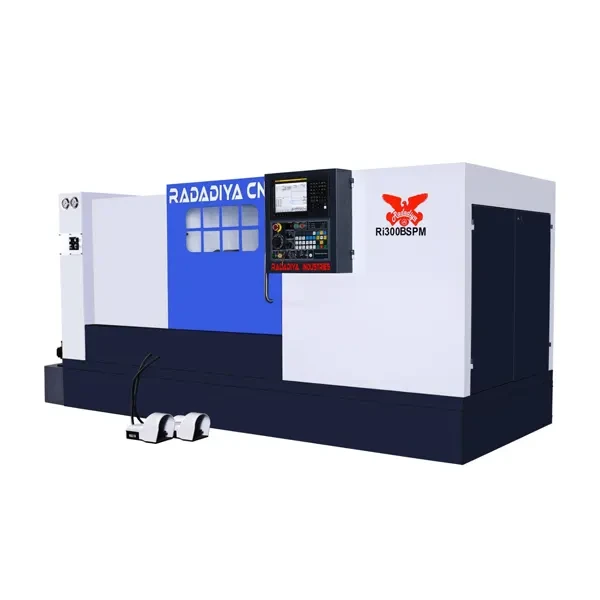

Cnc Pcd Drilling Machine

PCD Drilling Machine provides precise drilling with Polycrystalline Diamond (PCD) tools.

Ensuring high accuracy for hard materials. Designed for demanding industrial applications, it offers efficiency and consistent performance.

Silent Features:

- 360° Indexing Drilling Machine

- Ideal for PCD Drilling

- Rigid base and column design

- High Precision L.M. guide ways

- Fast Production

- Operator Friendly CNC machine

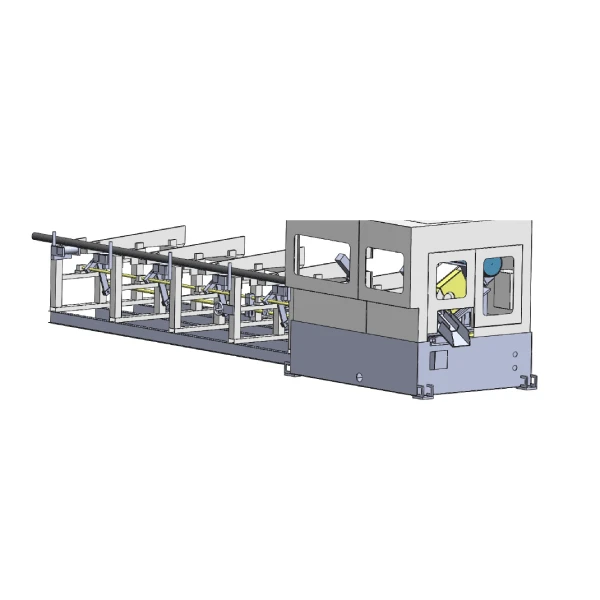

Cnc Pcd Drilling Machine

PCD Drilling Machine provides precise drilling with Polycrystalline Diamond (PCD) tools.

Ensuring high accuracy for hard materials. Designed for demanding industrial applications, it offers efficiency and consistent performance.

Silent Features:

- 360° Indexing Drilling Machine

- Ideal for PCD Drilling

- Rigid base and column design

- High Precision L.M. guide ways

- Fast Production

- Operator Friendly CNC machine

Product Specification

A CNC PCD (Polycrystalline Diamond) drilling machine offers significant benefits for precision drilling applications, particularly in hard and abrasive materials such as composites, ceramics, and various metals. The use of PCD tooling provides exceptional wear resistance and durability, allowing for longer tool life and reduced downtime for replacements. This translates to lower production costs and enhanced productivity, as the machine can maintain high cutting speeds without compromising quality.

The CNC technology ensures precise control over drilling parameters, enabling intricate and complex hole patterns with exceptional accuracy and repeatability. Additionally, the automated process minimizes human error and allows for efficient production runs, even in high-volume settings. By utilizing a CNC PCD drilling machine, manufacturers can achieve superior surface finishes, reduce the need for secondary operations, and improve overall machining efficiency, making it a valuable asset in industries such as aerospace, automotive, and electronics.