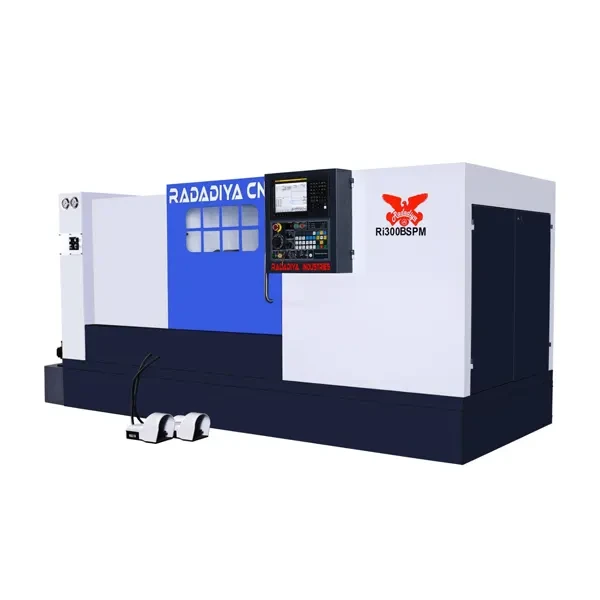

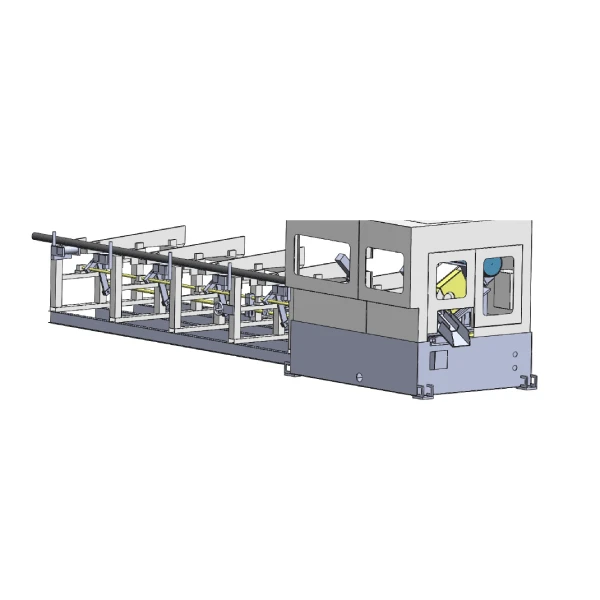

CNC Twin Spindle Turning Machine simultaneous machining operations on two workpieces.

Engineered for high precision, it delivers exceptional surface finishes and accuracy across various materials. It enables complex, multi-axis operations on both ends of a workpiece, improving overall productivity and precision in one setup.

- 45° Slant Bed Structure

- Rigid Headstock & Spindle

- Quang linear tooling with table surface with T-slot

- High Precision L.M. guide ways

- Centralized & Programmable Lubrication

- Operator Friendly CNC Machine